Automotive applications

N1001AUnreinforced grades

Wear resistance and low coefficient of friction are realized using our unique formulation technology.

Features

Features

- High slidability

Application examples

Application examples

Ties

Lock nut

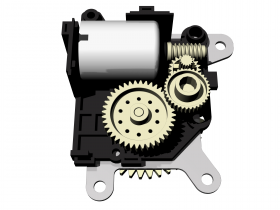

Gear etc. sliding parts

Physical properties table

Physical properties table

| Units | Test method | Grade | |

|---|---|---|---|

| Grade name | N1001A | ||

| Grade | Unreinforced grades | ||

| Glass fiber content | % | ― | 0 |

Basic physical properties

| Specific gravity | - | ISO 1183 | 1.11 |

|---|---|---|---|

| Water absorption rate(23℃ in water, 24hrs) | % | ISO 62 | 0.25 |

Mechanical properties

| Tensile strength | MPa | ISO 527 | 80 |

|---|---|---|---|

| Tensile elongation | % | ISO 527 | 12 |

| Flexural strength | MPa | ISO 178 | 105 |

| Flexural modulus | GPa | ISO 178 | 2.3 |

| Charpy impact strength with a notch | kJ/m2 | ISO 179/1eA | 9 |

Thermal properties

| Melting point | ℃ | ISO 11357-3 | 300 |

|---|---|---|---|

| Glass transition point | ℃ | ― | 125 |

| Deflection temperature under load(1.80MPa) | ℃ | ISO 75Af | 120 |

Dimensional properties

| Mold shrinkage(2mmt) :in direction of flow |

% | ISO 294-4 | 1.4 |

|---|---|---|---|

| :at right angles to flow | % | ISO 294-4 | 1.5 |

Slidability

| Limiting PV value | kg/cm2・cm/sec | JIS K7218-A | 1000 |

|---|---|---|---|

| Coefficient of dynamic friction P=10kgf/cm2 | ― | JIS K7218-A | 0.15 |

| Abrasion loss P=10kgf/cm2 | mg | JIS K7218-A | 20 |

*The above data are values measured by our company and do not guarantee performance.

Contact us

Kuraray Co., Ltd.

Genestar Division

-

North America+1-281-283-1712

Europe+32-3-250-9737

South America+55-11-2615-3531 - Contact us here