Electrical and electronic applications

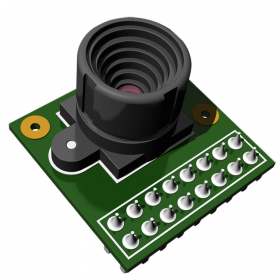

LA121Camera module

Genestar has low dust, high strength, and good moldability properties, making it a suitable material for camera module products.

Features

Features

- Camera module

Application examples

Application examples

Camera module

Physical properties table

Physical properties table

| Units | Test method | Grade | |

|---|---|---|---|

| Grade name | LA121 | ||

| Type | Camera module | ||

| Glass fiber content | % | ― | 35 |

Basic physical properties

| Specific gravity | - | ISO 1183 | 1.44 |

|---|---|---|---|

| Water absorption rate(23℃ in water, 24hrs) | % | ISO 62 | 0.10 |

| Flammability | - | UL94 | HB |

Mechanical properties

| Tensile strength | MPa | ISO 527 | 93 |

|---|---|---|---|

| Tensile elongation | % | ISO 527 | 1.3 |

| Flexural strength | MPa | ISO 178 | 163 |

| Flexural modulus | GPa | ISO 178 | 8.6 |

| Charpy impact Test (notched) | kJ/m2 | ISO 179/1eA | 1.8 |

Molding (flow) properties

| Bar flow length(320℃/0.5mmt/750kgf) | mm | - | 63 |

|---|

Dimensional properties

| Mold shrinkage (2mmt) :in direction of flow |

% | ISO 294-4 | 0.5 |

|---|---|---|---|

| :at right angles to flow | % | ISO 294-4 | 1.0 |

* "Halogen free" indicates less than 900-ppm Br, less than 900-ppm CI, and less than 1500-ppm total halogen content (BR, CI)

*These are standard values and are not specifications which guarantee performance.

Contact us

Kuraray Co., Ltd.

Genestar Division

-

North America+1-281-283-1712

Europe+32-3-250-9737

South America+55-11-2615-3531 - Contact us here